Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

Tel.: +86-13855519988

Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

Tel.: +86-13855519988The T-V type bending die is a special lower die structure designed for high-precision sheet metal bending. It utilizes a combination of a "T" shaped support and a 30° V-shaped opening, providing superior centering capability and stability. Its structure offers uniform support and precise positioning during the bending process, making it particularly suitable for bending thin sheets or workpieces requiring high surface quality. It is a commonly used high-performance die type for fine processing applications on CNC bending machines.

Product Name :

Durable 30 Degree T-V Press Brake Dies for Industrial BendingOrder(MOQ) :

1PCSPayment :

T/T,Western union,Alibaba,International Bank TransferMaterial :

42CrMo、Cr12MoVShipping Port :

Shanghai/Guangzhou or otherOEM/ODM :

support

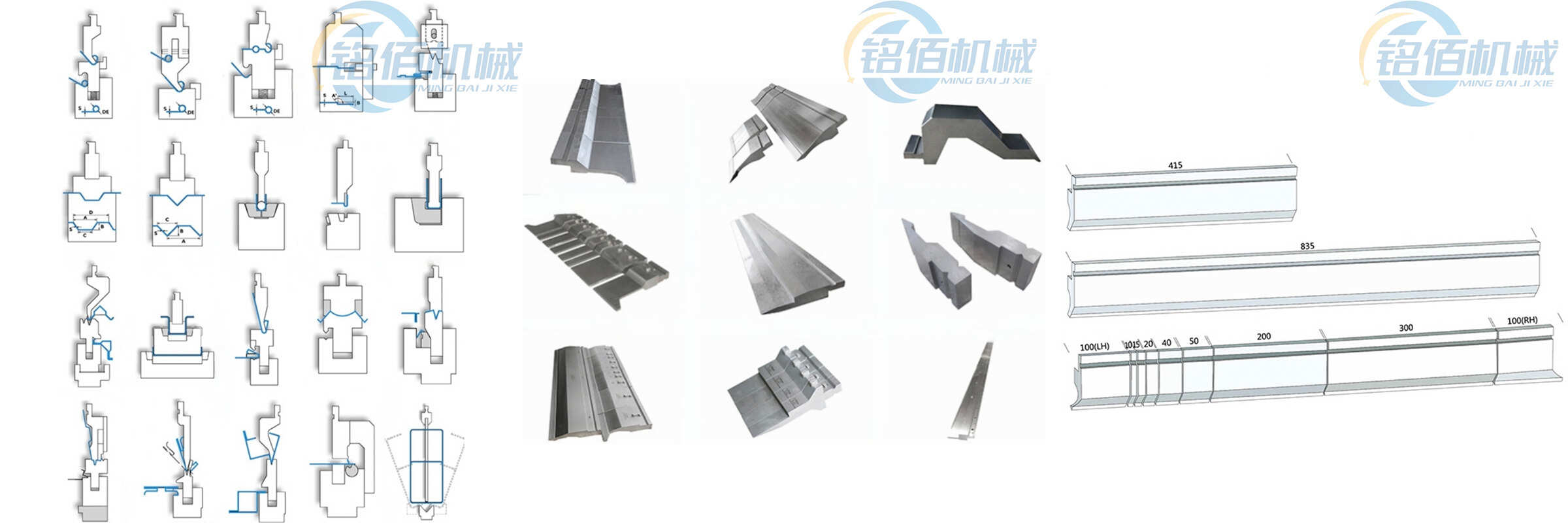

T-shaped Structure Design

This mold adopts a unique "T-shaped support" geometric design, which allows for more balanced force distribution on the workpiece during bending, reducing material slippage and angle deviation, preventing deformation and deflection of thin sheets, and improving bending consistency.

30° V-shaped Opening

The mold features a precision 30° opening angle design, achieving a tighter small inner radius bend, suitable for thin sheet materials and bending products with high aesthetic requirements, significantly improving bending quality.

Material Performance and Heat Treatment Process

Typically made of high wear-resistant mold steel (such as 42CrMo, Cr12MoV, T10, etc.), and treated with quenching, tempering, or high-frequency surface hardening, the mold possesses excellent wear resistance, compressive strength, and extended service life.

Precision Machining Process

The mold opening is processed by CNC grinding, ensuring high angle consistency and smooth edges, which helps reduce creases, indentations, and sheet metal damage; the mold bottom surface is precision ground to ensure flat and stable installation.

Wide Compatibility

Compatible with various CNC bending machines, including domestic CNC machine tools and international brands such as Amada, Bystronic, Accurpress, Durma, etc., supporting American or European standard specifications.

Applicable Scenarios

This mold is widely used for high-quality metal bending in:

Electrical enclosures and cabinet doors

Precision instrument housings

Stainless steel kitchen equipment

Small equipment sheet metal parts

Decorative metal sheet bending

Aluminum and stainless steel thin sheet processing

Optional Specifications and Customization

Supports V-groove width selection, mold length segmentation, material upgrades (such as titanium plating, nitriding, etc.), and non-standard angle customization to meet different customer processing needs.

Our production process:

1.Cutting

2.Forging

3.Plastic surgery

4.Heat treatment

5.Modification

6.Slice

7.Initial grinding

8.Sharpen

9.Plastic surgery

10.Fine grinding

11.Plastic surgery

12.Chamfer

13.Test

14.Package

15.Factory

Our products serve all walks of life:

Suitable for cartons, corrugated paper, gift boxes, advertising industry chevron board, KT board, cardboard cutting, clothing fabrics, carbon fiber and glass fiber, various papers, films, PET, automobile wire ring mats, various composite materials fully surrounded mats, rubber, gray board, plastic, embroidery materials, automobiles, carriages, papermaking, textiles, metallized film, tobacco, packaging materials, BOPP film, food machinery, medicinal materials, aluminum foil, metallized film, tobacco, electronics, light industry, food, leather, chemical fiber, glass fiber, textiles, stationery, plastics, feed, paper tubes, cartons, woodworking and other industries.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1: Are you a trading company or a factory?

We are a factory with 30 years of experience in blade production.

2: Do you accept custom blades?

Of course. We can produce blades in various shapes, sizes, and materials to suit your needs.

3: Do you have a complete processing facility? What is the precision?

We use a complete set of blade processing machinery, and CNC machining ensures blade flatness accuracy of 0.001.

4: What trading terms do you accept?

If you have a preferred trading term, please let our customer service know. If not, we accept delivery by delivery, FOB, CFR, CIF, etc.

5: What is the quality of the blades?

Our blades utilize advanced technology. Furthermore, we conduct strict inspections during the production process to ensure the high quality of each finished product.

leave a message

Scan to wechat :

Scan to whatsapp :