Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

Tel.: +86-13855519988

Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

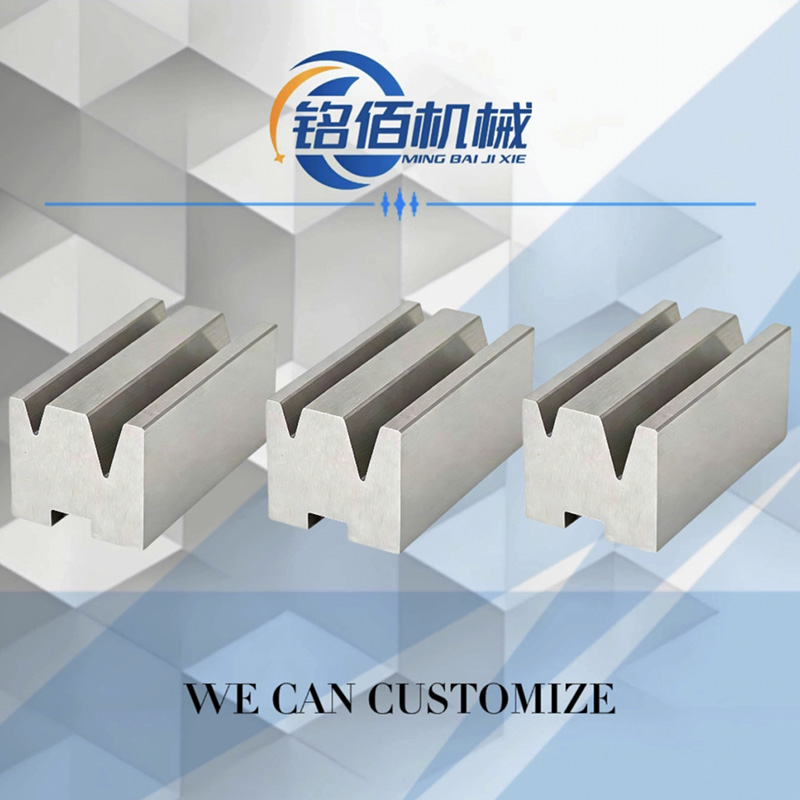

Tel.: +86-13855519988The self-centering 2V bending die is a versatile and highly stable lower die type, featuring a double V-groove structure and self-centering positioning design. It is adaptable to bending operations across a range of sheet metal thicknesses. Widely used in high-standard sheet metal processing, this die ensures consistent bending centers and precise angles, improving production efficiency. It is a very common die configuration in precision bending applications.

Product Name :

press brake self centering 2v dies with standard punchOrder(MOQ) :

1PCSPayment :

T/T,Western union,Alibaba,International Bank TransferMaterial :

42CrMo、Cr12MoVShipping Port :

Shanghai/Guangzhou or otherOEM/ODM :

support

Dual V-Groove Design

The mold design features two V-shaped openings of different widths, allowing for easy switching between bending requirements. This design is suitable for various sheet thicknesses and bending angles, significantly improving mold versatility and ease of operation.

Self-Centering Positioning Function

The self-centering structure ensures that the bending pressure point remains consistently centered. Even when switching between different V-grooves, the bending line accuracy remains consistent, reducing debugging time and improving product consistency.

High-Strength Material and Heat Treatment

Manufactured from alloy tool steel (such as T8 / 42CrMo / Cr12MoV), and subjected to tempering and high-frequency quenching or overall heat treatment, the mold possesses excellent hardness, wear resistance, and compressive strength, suitable for long-term high-load use.

Precision and Surface Finish

The cutting edge and forming surface are precisely ground, with strictly controlled angle tolerances and a smooth surface, reducing the risk of scratching, indentation, and burrs on the sheet metal during bending.

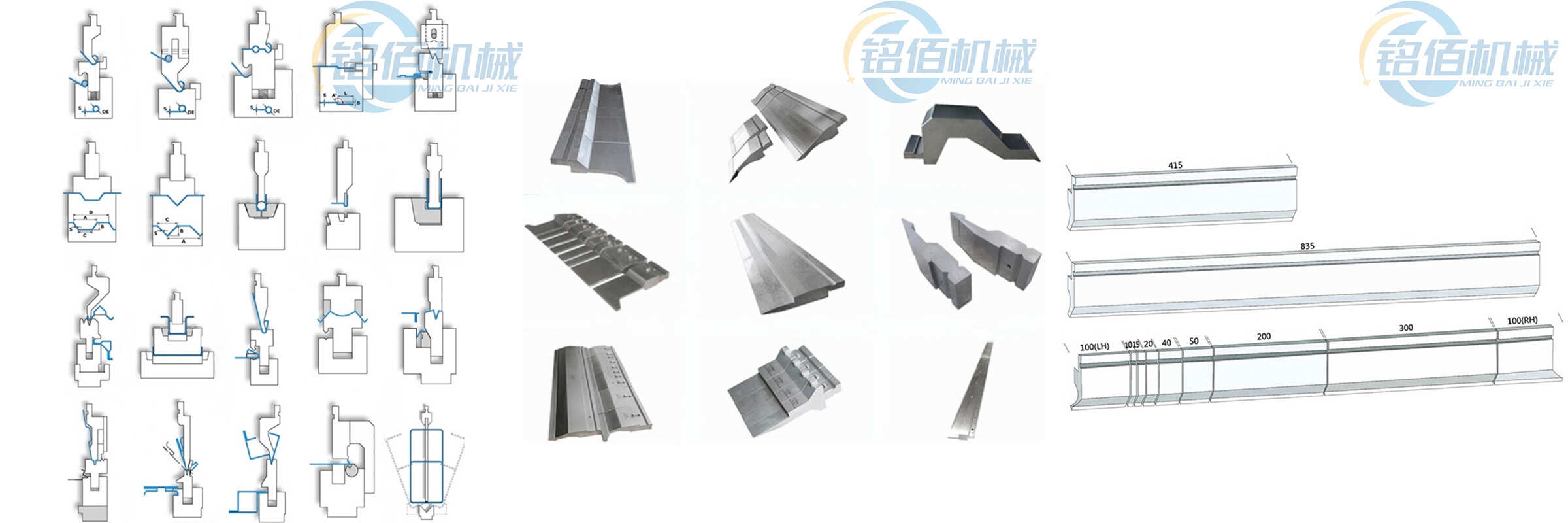

Wide Compatibility

Suitable for most domestic and imported CNC bending machines, including Amada, Accurpress, Durma, Bystronic, etc., with American/European style mounting interfaces available.

Application Industries

Suitable for:

Sheet metal processing plants and OEM manufacturers

Electrical system enclosures and cabinets

Stainless steel casings and decorative parts

Mechanical equipment structural components

Household appliance metal parts

Automotive and engineering manufacturing components

Multiple Specifications & Customization Support

Various V-groove sizes, mold heights, lengths, and segmented forms are available according to customer needs. Hardening treatment or coating options are also available to meet different material and production conditions.

Our production process:

1.Cutting

2.Forging

3.Plastic surgery

4.Heat treatment

5.Modification

6.Slice

7.Initial grinding

8.Sharpen

9.Plastic surgery

10.Fine grinding

11.Plastic surgery

12.Chamfer

13.Test

14.Package

15.Factory

Our products serve all walks of life:

Suitable for cartons, corrugated paper, gift boxes, advertising industry chevron board, KT board, cardboard cutting, clothing fabrics, carbon fiber and glass fiber, various papers, films, PET, automobile wire ring mats, various composite materials fully surrounded mats, rubber, gray board, plastic, embroidery materials, automobiles, carriages, papermaking, textiles, metallized film, tobacco, packaging materials, BOPP film, food machinery, medicinal materials, aluminum foil, metallized film, tobacco, electronics, light industry, food, leather, chemical fiber, glass fiber, textiles, stationery, plastics, feed, paper tubes, cartons, woodworking and other industries.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1: Are you a trading company or a factory?

We are a factory with 30 years of experience in blade production.

2: Do you accept custom blades?

Of course. We can produce blades in various shapes, sizes, and materials to suit your needs.

3: Do you have a complete processing facility? What is the precision?

We use a complete set of blade processing machinery, and CNC machining ensures blade flatness accuracy of 0.001.

4: What trading terms do you accept?

If you have a preferred trading term, please let our customer service know. If not, we accept delivery by delivery, FOB, CFR, CIF, etc.

5: What is the quality of the blades?

Our blades utilize advanced technology. Furthermore, we conduct strict inspections during the production process to ensure the high quality of each finished product.

leave a message

Scan to wechat :

Scan to whatsapp :