Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

Tel.: +86-13855519988

Email: Mb@mingbaiblade.com

Email: Mb@mingbaiblade.com Tel.: +86-13855519988

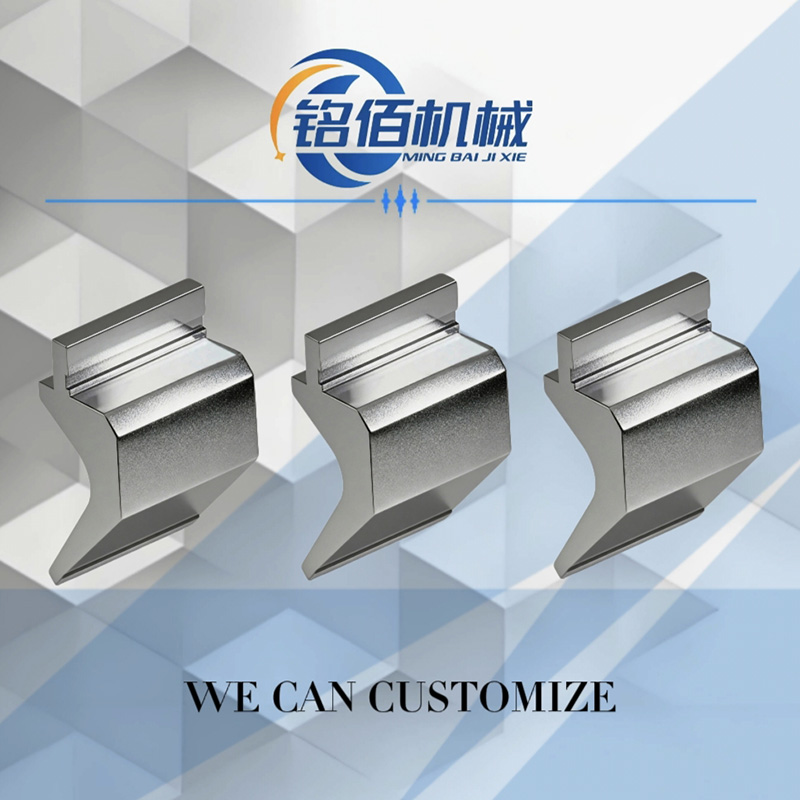

Tel.: +86-13855519988The standard gooseneck upper die for bending machines is a commonly used type of upper die widely applied in sheet metal bending processes. Its unique gooseneck (C-shaped) structure effectively avoids interference with the edges of already formed workpieces, making it particularly suitable for multi-stage bending, complex shapes, and deep box-shaped workpieces. This die combines versatility and practicality, making it an indispensable basic tool in the sheet metal processing industry.

Product Name :

Bending machine gooseneck upper dieOrder(MOQ) :

1PCSPayment :

T/T,Western union,Alibaba,International Bank TransferMaterial :

2CrMo、Cr12MoV.etcShipping Port :

Shanghai/Guangzhou or otherOEM/ODM :

support

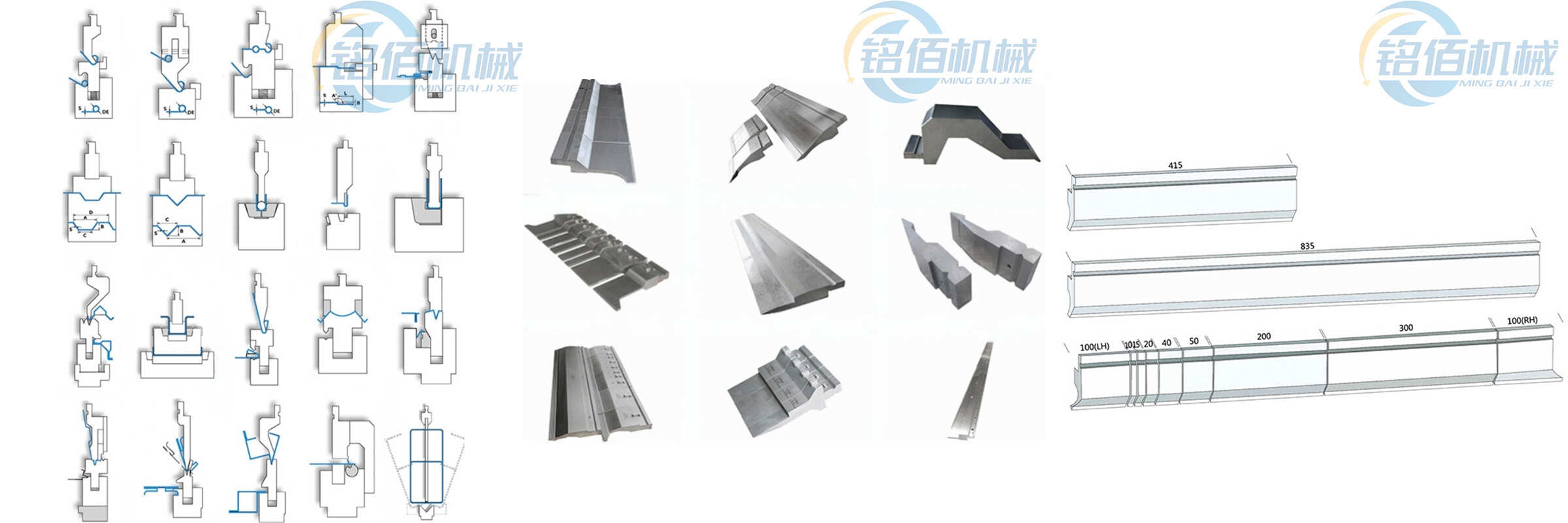

Structural Features

The gooseneck upper die features a curved neck design, allowing the die to avoid contact with the workpiece sidewall during bending, reducing the risk of interference and improving the forming capability of complex workpieces. It is especially suitable for box-shaped parts, U-shaped parts, and multi-bend processes.

Material and Heat Treatment

The die is typically made of high-strength alloy tool steel (such as 42CrMo, Cr12MoV, etc.), and undergoes overall tempering and surface hardening treatment, possessing high hardness, high wear resistance, and good impact resistance, ensuring long-term stable use.

Precision and Compatibility

Manufactured strictly according to international standards, with precise angles and high linearity, it is compatible with mainstream bending machines (such as Amada, Trumpf, Bystronic, and domestic bending machines). Standard connection methods are available for easy and quick installation and replacement.

Application Scope

Widely used in industries such as chassis and cabinets, electrical equipment, sheet metal enclosures, stainless steel products, and mechanical equipment structural parts, it is suitable for bending processing of various materials including carbon steel, stainless steel, and aluminum plates.

Customizable Service

In addition to standard specifications, non-standard customization services are available based on customer drawings or processing requirements, including die height, angle, gooseneck depth, and surface treatment methods, to meet different production conditions.

Our production process:

1.Cutting

2.Forging

3.Plastic surgery

4.Heat treatment

5.Modification

6.Slice

7.Initial grinding

8.Sharpen

9.Plastic surgery

10.fine grinding

11.Plastic surgery

12.Chamfer

13.Test

14.Package

15.Factory

Our products serve all walks of life:

Suitable for cartons, corrugated paper, gift boxes, advertising industry chevron board, KT board, cardboard cutting, clothing fabrics, carbon fiber and glass fiber, various papers, films, PET, automobile wire ring mats, various composite materials fully surrounded mats, rubber, gray board, plastic, embroidery materials, automobiles, carriages, papermaking, textiles, metallized film, tobacco, packaging materials, BOPP film, food machinery, medicinal materials, aluminum foil, metallized film, tobacco, electronics, light industry, food, leather, chemical fiber, glass fiber, textiles, stationery, plastics, feed, paper tubes, cartons, woodworking and other industries.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1: Are you a trading company or a factory?

We are a factory with 30 years of experience in blade production.

2: Do you accept custom blades?

Of course. We can produce blades in various shapes, sizes, and materials to suit your needs.

3: Do you have a complete processing facility? What is the precision?

We use a complete set of blade processing machinery, and CNC machining ensures blade flatness accuracy of 0.001.

4: What trading terms do you accept?

If you have a preferred trading term, please let our customer service know. If not, we accept delivery by delivery, FOB, CFR, CIF, etc.

5: What is the quality of the blades?

Our blades utilize advanced technology. Furthermore, we conduct strict inspections during the production process to ensure the high quality of each finished product.

leave a message

Scan to wechat :

Scan to whatsapp :